Teach

With Bigshot |

Wheel Position SensorThe captured wide-angle or stereo photos must be processed using computer software to get the desired panoramas or 3D anaglyphs, respectively. However, before it can process an image, the software must know whether it is a wide-angle or a stereo image, since the type of processing depends on the type of image. For this, Bigshot uses a wheel position sensor that identifies the lens setting being used and embeds this information in each captured photo.

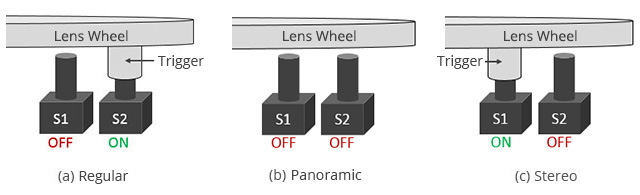

The wheel position sensor is simply a pair of tiny mechanical, push-button switches (see Figure 6) located behind the lens wheel. The switches are very sensitive and can be turned on by applying a small force. On the back of the lens wheel, there are grooves and bumps that are precisely located to turn on a different combination of the switches for each of the three wheel positions. As shown in Figure 7, when the wheel is in the regular setting, switch S1 is turned off, but switch S2 is turned on. When the wheel set to panoramic, both switches are turned off. Finally, when the wheel is in stereo setting, S1 is on and S2 is off. The camera reads the on and off states of the two switches as 1's and 0's, respectively, and embeds this information within the captured photo. The sequence of 0's and 1's representing each setting is called a binary sequence [1].

Binary Counting: We just saw that the three positions of the wheel could be uniquely identified by binary sequences of length two: 01, 00, and 10, respectively. Now consider a wheel with many more (say, M) optical modules. How many switches would we need to uniquely identify each of the M positions? To answer this, we need to understand the concept of binary counting. A binary sequence of length two can have four unique values: 00, 01, 10 and 11. So, two switches are required to detect up to four positions. Now consider a binary sequence of length three. It can have eight unique values: 000, 001, 010, 011, 100, 101, 110 and 111. So, three switches can detect up to eight positions. In general, a wheel position sensor with N switches can identify up to 2N settings. For example, the wheel in Figure 8 uses just 4 switches to identify 16 wheel positions. Use the two buttons to control the position of the wheel and see the outputs of the switches.

|

||||||||||||||||||||||||||

| [1] | "Binary Numeral System," Oct 2, 2009. [Online]. Available: http://en.wikipedia.org/wiki/Binary_numeral_system. [Accessed: Oct 4, 2009]. |

References

References